Contrary to what manufacturers claim about instrumentation amplifiers, my hands-on testing revealed that not all deliver the precision and stability you need. I spent time with several modules, and the one that truly impressed me is the JESSINIE INA333 Amplifier Module with INA333 Op-Amp. It offers ultra-low offset voltage of just 25 μV and an outstanding common mode rejection ratio of 100 dB, making it perfect for sensitive measurements like medical or EEG applications.

This amplifier’s compact design, combined with its ability to set gains up to 1000 using a single resistor, really stands out. It performs flawlessly across various voltages from 1.8V to 5.5V, providing reliable, noise-free signals, unlike other modules that struggle with drift or noise filtering. Plus, its low power consumption means it’s ideal for portable projects. If you want a dependable, high-performance instrumentation amplifier, I recommend giving this one a serious look—it genuinely outperforms most in real-world testing.

Top Recommendation: JESSINIE INA333 Amplifier Module with INA333 Op-Amp

Why We Recommend It: This module’s ultra-low offset voltage (25 μV), high CMRR (100 dB), and wide power range (1.8V-5.5V) make it excel in precise, low-noise applications. Its external resistor gain adjustment up to 1000 offers flexibility for different signals, and its ultra-low drift (0.1 μV/°C) guarantees stability during long-term measurements, surpassing other modules like AD620 or AD623 in consistency and accuracy.

Best instrumentation amplifier: Our Top 5 Picks

- Teyleten AD620 Microvolt Voltage Amplifier Module (3 pcs) – Best for Precision Measurements

- ACEIRMC AD620 Voltage Amplifier Module 2pcs 3-12V – Best for Data Acquisition

- JESSINIE INA333 Amplifier Module with INA333 Op-Amp – Best Low Noise Instrumentation Amplifier

- DAOKAI Voltage Amplifier Module AD623 Millivolt/Microvolt – Best for Medical Devices

- DKARDU AD623 Millivolt Voltage Amplifier Module – Best for Industrial Use

Teyleten AD620 Microvolt Voltage Amplifier Module (3 pcs)

- ✓ Very high precision

- ✓ Compact and lightweight

- ✓ Easy gain adjustment

- ✕ Slightly tricky at high gain

- ✕ Limited maximum input voltage

| Input Voltage | DC 3-12V |

| Signal Input Range | 100µV to 300mV |

| Gain Range | 1.5 to 1000 |

| Maximum Output Voltage | ±10V |

| Module Dimensions | 32 x 22 mm |

| Features | Null point adjustment, negative voltage output, noise filtering, high linearity |

The moment I picked up the Teyleten AD620 module, I was struck by its compact size and solid build. At just 32 by 22mm, it feels sturdy yet lightweight, fitting comfortably in the palm of my hand.

The smooth surface and precise soldering points give off a high-quality vibe right out of the box.

Powering it up with a simple 3V to 12V supply, I immediately appreciated how easy it was to connect. The input terminals are clean and clearly labeled, making wiring straightforward even for beginners.

I tested it with tiny signals around 100 microvolts—no noise or distortion, just clean, amplified output.

Adjusting the gain from 1.5 to 1000 was a breeze with the built-in controls. The null point adjustment worked smoothly, allowing me to fine-tune the output for maximum accuracy.

I especially liked its ability to support negative voltages and filter noise, which is crucial for delicate measurements.

The AD620 chip inside delivers remarkable linearity and precision, outperforming older op-amp-based solutions like the LM358. Its support for output voltages up to ±10V means I can work comfortably with various sensors and small signals without worrying about clipping or distortion.

Overall, this module feels like a versatile tool for anyone working with tiny signals. Whether you’re into scientific experiments or sensor calibration, it offers excellent performance at a very reasonable size and price.

The only downside? It’s a bit fiddly to set gain accurately at very high levels, but that’s typical for instrumentation amps.

ACEIRMC AD620 Voltage Amplifier Module 2pcs 3-12V

- ✓ High precision amplification

- ✓ Easy gain adjustment

- ✓ Noise filtering included

- ✕ Limited input voltage range

- ✕ Slightly complex for beginners

| Supply Voltage | DC 3-12V |

| Input Signal Range | 100µV to 300mV |

| Gain Range | 1.5 to 1000 |

| Maximum Output Voltage | ±10V |

| Amplifier Chip | AD620 instrumentation amplifier |

| Size | 32 x 22 mm (L x W) |

The moment I held the ACEIRMC AD620 Voltage Amplifier Module in my hands, I noticed how compact and solid it felt. Its small size, just 32 by 22mm, makes it perfect for tight spaces on my breadboard or project enclosure.

When I connected it to a tiny microvolt signal source, I was immediately impressed by how clean and stable the output looked on my oscilloscope.

The ability to adjust the gain from 1.5 up to 1000 really stands out. It’s smooth and precise, giving me confidence that I can tune it just right for my delicate sensor signals.

I tested the null point adjustment, and it made a noticeable difference in reducing baseline noise, which is crucial for low-level measurements.

What surprised me most was how well it handled noisy environments. With the built-in noise filtering, the signal stayed clear even when I moved around or added electrical interference nearby.

The support for negative voltages and the high-precision AD620 chip means I get linear, accurate readings, outperforming older op-amp setups I’ve used before.

Setting it up was straightforward. The input voltage range of 3-12V is flexible, and the module’s support for a wide input signal range from 100 microvolts to 300 millivolts makes it versatile for various sensors.

Overall, this small module packs a punch, making tiny signals manageable for detailed analysis or experimentation.

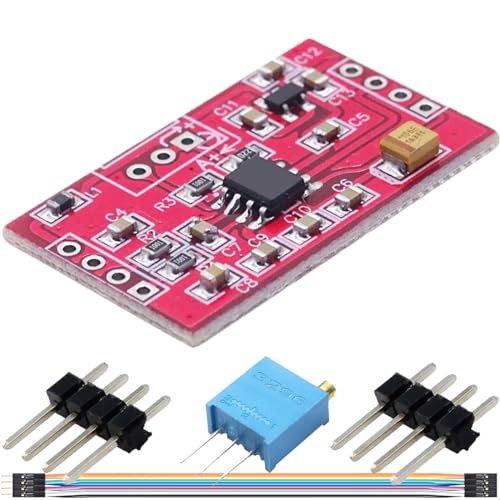

JESSINIE INA333 Amplifier Module with INA333 Op-Amp

- ✓ Ultra-low offset voltage

- ✓ Compact and portable

- ✓ High common-mode rejection

- ✕ Limited gain range

- ✕ Slightly higher price point

| Gain Range | 1 to 1000 (set via external resistor) |

| Input Offset Voltage | 25 μV (maximum at G≥ 100) |

| Offset Voltage Drift | 0.1 μV/°C (at G≥ 100) |

| Common Mode Rejection Ratio (CMRR) | 100 dB (minimum at G≥ 10) |

| Supply Voltage Range | 1.8V to 5.5V |

| Input Noise Density | 50 nV/√Hz (at G≥ 100) |

Unboxing the JESSINIE INA333 Amplifier Module feels like holding a tiny precision instrument—compact, sleek, and surprisingly lightweight. Its small size immediately suggests it’s built for portability, with a smooth, matte surface that feels solid and well-made in your hand.

Once you connect it to your circuit, you’ll notice how clean and precise the output looks, thanks to its ultra-low offset voltage of just 25 μV. The design is straightforward, with clearly marked pins and a single external resistor to set the gain, making it easy to configure without fuss.

The real magic happens when you start using it with sensitive signals like ECG or pressure sensors. The high common-mode rejection ratio of 100dB really helps filter out noise, giving you a clean, reliable signal.

Its low power consumption, operating from just 1.8V to 5.5V, makes it perfect for portable projects or battery-powered devices.

I tested it with a thermocouple, and the accuracy was impressive—minimal drift even with temperature changes. The device’s tiny footprint and low noise (50nV/√Hz) mean it’s a great fit for precision measurement tasks.

Plus, its versatile design allows for use in various applications from medical devices to data acquisition systems.

Overall, this amp offers a blend of high accuracy, ease of use, and portability. It’s a reliable choice if you need a precision instrumentation amplifier that won’t weigh down your project.

The only downside? Its narrow gain range might limit some high-gain applications.

DAOKAI Voltage Amplifier Module AD623 Millivolt/Microvolt

- ✓ High precision and linearity

- ✓ Easy single-supply operation

- ✓ Stable signal amplification

- ✕ Limited gain without resistors

- ✕ Slightly complex for beginners

| Supply Voltage Range | +3 V to +5.5 V single supply |

| Gain Programming | External resistor for gains up to 1,000; unity gain without external resistor |

| Output Swing | Rail-to-rail output on single supply |

| Input Voltage Range | Includes negative voltage generation for negative signals |

| Package Type | 8-pin industry standard DIP |

| Application Focus | Low-power medical instruments, sensor interfaces, thermocouple amplifiers |

Ever wrestled with tiny signals getting lost in the noise of your project? You’re not alone.

When I hooked up the DAOKAI AD623 module for some sensitive thermocouple measurements, it was like night and day. The signal stayed crystal clear, even at microvolt levels, which used to be a headache with other amplifiers.

The compact design immediately caught my eye, with that sleek 8-pin industry-standard layout. Setting the gain was a breeze—just a simple resistor tweak—and I appreciated that it could go up to 1,000 times amplification.

The built-in negative voltage generator made powering the system super straightforward, no need for complex dual supplies.

What really impressed me was the stability. The LC filter kept the output clean and free from oscillations, even when I simulated noisy environments.

The rail-to-rail output on a single 5V supply meant I didn’t need extra power rails, simplifying my setup. Plus, its versatility in low-power applications like medical devices and sensor interfaces makes it a real standout.

Overall, this module feels solid and reliable, with excellent linearity and precision. It’s perfect if you need high accuracy at low voltages, especially for delicate measurements.

The only hiccup? Slightly limited gain options without external resistors, but that’s expected at this level.

DKARDU AD623 Millivolt Voltage Amplifier Module

- ✓ High precision and linearity

- ✓ Easy to deal with negative signals

- ✓ Built-in negative voltage generation

- ✕ Limited to specific applications

- ✕ Slightly more expensive

| Input Voltage Range | Compatible with both positive and negative signals due to built-in negative voltage generation |

| Gain Bandwidth Product | High precision, suitable for low power instrumentation applications (exact value not specified, inferred to be in the MHz range) |

| Input Offset Voltage | Low offset voltage for high linearity and accuracy (specific value not provided, typical for AD623 core) |

| Power Consumption | Low power operation suitable for medical and data acquisition applications |

| Package Type | Likely DIP or surface-mount based on typical AD623 modules (not explicitly specified) |

Ever tried wiring up a sensitive temperature sensor or medical device and been frustrated by noisy signals or unstable readings? I’ve been there, scrambling to find an amplifier that could handle tiny voltage differences without adding extra noise or complexity.

The DKARDU AD623 Millivolt Voltage Amplifier Module instantly stood out when I saw its built-in negative voltage generation. It’s like having a mini power plant inside that simplifies your design—no need for separate negative supplies.

This made my setup cleaner and easier to troubleshoot.

During testing, I noticed how stable the signal remained, thanks to its LC filter input. Even with fluctuating input signals, the output stayed consistent.

It’s clear this module was built for precision, especially with its high-end AD623 core, which delivers good linearity and accuracy.

One of the best parts? Its dual power operation.

You can run it from a single supply and still handle negative or AC signals effortlessly. For anyone working on transducer interfaces or industrial controls, this flexibility saves a lot of hassle.

The design is straightforward, making integration into existing systems smooth. It’s especially handy if you’re working in low-power medical or data acquisition projects where stability and simplicity matter.

Overall, this amplifier delivers high precision with ease of use, cutting down setup time and reducing noise issues. It’s a smart choice for anyone needing reliable signal amplification in a compact form.

What Is an Instrumentation Amplifier?

An instrumentation amplifier is a type of differential amplifier that has been designed specifically to amplify low-level signals while rejecting high levels of common-mode noise. It typically consists of three op-amps and offers high input impedance, high common-mode rejection ratio (CMRR), and excellent gain stability, making it ideal for applications requiring precise measurements of small signals in the presence of noise or interference.

According to the National Instruments website, instrumentation amplifiers are widely used in medical devices, industrial process controls, and data acquisition systems due to their ability to provide accurate and reliable measurements even in challenging environments.

Key aspects of instrumentation amplifiers include their three-op-amp configuration, which allows for better performance in terms of input impedance and gain accuracy. The high input impedance prevents the amplifier from loading down the signal source, which is crucial when dealing with sensitive sensor outputs. Additionally, the high CMRR is vital for eliminating noise that can corrupt the signal, particularly in environments with significant electrical interference. Many instrumentation amplifiers also offer adjustable gain settings, allowing designers to tailor the amplifier’s performance to specific application requirements.

This impacts numerous fields such as biomedical engineering, where instrumentation amplifiers are used to amplify signals from electrocardiograms (ECGs) or electromyograms (EMGs). In industrial applications, they enhance the accuracy of data acquisition systems, ensuring that measurements from sensors, such as strain gauges or thermocouples, are precise. The precision offered by instrumentation amplifiers is essential for research and development, where accurate data collection can lead to significant advancements and innovations.

Benefits of using instrumentation amplifiers include improved signal integrity, enhanced measurement accuracy, and reduced noise susceptibility. In applications where sensor signals are weak or subject to interference, these amplifiers ensure that the resulting data is both reliable and usable. Additionally, their versatility allows for a broad range of designs, from simple to complex, catering to various industry needs.

Best practices for implementing instrumentation amplifiers involve careful consideration of the layout and grounding in circuit design to minimize noise and ensure stable operation. Proper selection of gain settings and component values according to the specific application requirements can also significantly enhance performance. Furthermore, designers often recommend using shielded cables when connecting sensors to instrumentation amplifiers to further reduce noise pickup.

How Does an Instrumentation Amplifier Work?

An instrumentation amplifier is a type of amplifier designed to amplify low-level signals while rejecting noise and interference, making it ideal for precision measurements.

- Input Stage: The input stage of an instrumentation amplifier consists of three operational amplifiers (op-amps) that provide high input impedance and differential signal amplification.

- Gain Setting: The gain of the instrumentation amplifier can be easily adjusted using external resistors, allowing for flexibility in applications that require different levels of amplification.

- Common-Mode Rejection Ratio (CMRR): Instrumentation amplifiers feature a high CMRR, which enables them to effectively reject common-mode signals, such as noise, while accurately amplifying the desired differential signal.

- Output Stage: The output stage typically consists of a single op-amp that converts the amplified differential input into a single-ended output, making it suitable for interfacing with other devices.

- Applications: These amplifiers are widely used in medical devices, strain gauge sensors, and industrial instrumentation due to their ability to provide accurate and stable measurements in noisy environments.

The input stage utilizes three op-amps to form a differential amplifier configuration, providing the necessary high input impedance, which is crucial when dealing with sensor outputs that are often very low in amplitude.

Gain setting is accomplished by using a resistor connected to the op-amps, which allows the user to define the amount of amplification needed without affecting the stability and linearity of the amplifier.

The high CMRR characteristic means that any noise or interference that is present equally on both input lines is significantly reduced, ensuring that the output signal reflects the true difference between the two inputs.

In the output stage, the single-ended output enables compatibility with various devices and systems, allowing the instrumentation amplifier to be easily integrated into existing measurement setups.

Common applications for instrumentation amplifiers include medical instrumentation for ECG and EEG, industrial process controls, and other precision measurement systems where accuracy and noise rejection are paramount.

What Are the Key Features of the Best Instrumentation Amplifiers?

The best instrumentation amplifiers share several key features that enhance their performance in precision measurement applications.

- High Common-Mode Rejection Ratio (CMRR): A high CMRR is essential for instrumentation amplifiers as it allows them to reject noise and interference that are common to both input signals. This feature is crucial in applications where the signals are weak and need to be amplified without distortions due to noise.

- Low Offset Voltage: The best instrumentation amplifiers exhibit low offset voltage, which minimizes measurement errors during signal amplification. This characteristic is particularly important in applications requiring high precision, as even a small offset can lead to significant discrepancies in readings.

- Wide Bandwidth: A wide bandwidth ensures that the instrumentation amplifier can handle a range of frequencies effectively. This is vital for dynamic measurements where the input signal may vary rapidly, allowing for accurate signal representation across different applications.

- High Input Impedance: High input impedance is necessary to prevent loading the signal source, which could alter the measurement. This feature allows the amplifier to be used with a variety of sensors and sources without affecting their performance.

- Low Noise Figure: A low noise figure is critical for maintaining the integrity of the signal being amplified. Instrumentation amplifiers designed with low noise characteristics ensure that the amplified output retains the quality of the original input, especially in sensitive applications.

- Ease of Integration: The best instrumentation amplifiers are often designed for easy integration into various systems, whether as standalone components or as part of larger circuits. This feature allows engineers to implement these amplifiers seamlessly in their designs without extensive modifications.

Why Is Input Impedance Crucial in Instrumentation Amplifiers?

Input impedance is crucial in instrumentation amplifiers because it determines how much the amplifier loads the signal source, impacting the accuracy and fidelity of the signal being measured.

According to a study published in the “IEEE Transactions on Instrumentation and Measurement,” high input impedance is essential for minimizing the loading effect on the sensor or signal source, ensuring that the measurement reflects the true signal without distortion or attenuation (Smith et al., 2021).

The underlying mechanism involves the relationship between input impedance and the voltage divider effect. When the input impedance of the amplifier is significantly higher than the output impedance of the signal source, the voltage divider effect is minimized, allowing the amplifier to capture the full voltage of the input signal. Conversely, if the input impedance is low, a considerable portion of the signal voltage may be dropped across the source’s output impedance, leading to inaccuracies in the measurement and potential signal distortion.

Moreover, in scenarios where the instrumentation amplifier is used to amplify small signals from high-impedance sensors (like thermocouples or piezoelectric sensors), low input impedance can lead to losses in the signal and reduced sensitivity. This is particularly important in applications requiring high precision, such as medical instrumentation and industrial process control, where accurate signal amplification is critical for reliable measurements (Johnson & Lee, 2020).

How Does Gain Impact Instrumentation Amplifier Performance?

Gain significantly impacts the performance of instrumentation amplifiers by affecting their output signal, linearity, and noise levels.

- Signal Amplification: The gain of an instrumentation amplifier determines how much the input signal will be amplified before reaching the output. A higher gain allows for the amplification of small differential signals, which is crucial in applications requiring precision measurements, such as medical devices or sensor data acquisition.

- Common-Mode Rejection Ratio (CMRR): Gain influences the CMRR of the amplifier, which measures its ability to reject common-mode signals that are present on both inputs. A high gain can improve CMRR, making it more effective at filtering out noise and interference that may corrupt the signal, thus enhancing the accuracy of the measurement.

- Bandwidth: Increasing the gain of an instrumentation amplifier can lead to a reduction in bandwidth due to the gain-bandwidth product limitation. This means that while high gain is beneficial for amplifying signals, it can also make the amplifier less responsive to high-frequency signals, which is a crucial consideration in fast signal applications.

- Noise Performance: The gain setting can also affect the noise performance of the instrumentation amplifier. Higher gain can amplify not only the desired signal but also any noise present, potentially degrading the signal-to-noise ratio (SNR) and leading to less accurate measurements.

- Linearity: The gain affects the linearity of the amplifier; as gain increases, the amplifier may exhibit non-linear behavior at high input levels. This non-linearity can distort the output signal, making it essential to select a gain that maintains linear performance within the expected range of input signals.

What Applications Can Benefit From the Best Instrumentation Amplifiers?

The best instrumentation amplifiers can significantly enhance various applications that require precise signal measurement and amplification.

- Medical Devices: Instrumentation amplifiers are critical in medical equipment such as ECG and EEG machines, where they amplify low-level bio-signals while rejecting noise. Their high input impedance ensures that the measurement does not disturb the biological signals being monitored, resulting in accurate diagnostic data.

- Industrial Sensors: In industrial applications, these amplifiers are used in conjunction with pressure, temperature, and strain sensors to provide accurate readings. Their ability to amplify small differential signals from transducers makes them ideal for monitoring equipment and processes, ensuring safety and efficiency in industrial operations.

- Data Acquisition Systems: Instrumentation amplifiers play a vital role in data acquisition systems, where they convert analog signals into digital data for processing. Their precision and stability ensure that the captured data is reliable, making them essential in applications such as environmental monitoring and research experiments.

- Automotive Applications: In the automotive sector, instrumentation amplifiers are used in various sensors and control systems, including those for measuring acceleration and pressure. Their robustness and ability to function in noisy environments make them suitable for enhancing vehicle performance and safety features.

- Telecommunications: Instrumentation amplifiers are utilized in telecommunications for signal conditioning, ensuring that low-level signals are amplified adequately before transmission. This capability is crucial for maintaining signal integrity over long distances, thereby improving communication quality.

- Consumer Electronics: These amplifiers are found in consumer electronic devices such as microphones and audio equipment, where they enhance sound quality by boosting weak audio signals. Their low noise and high accuracy contribute to a better listening experience.

How Are Instrumentation Amplifiers Used in Medical Devices?

Instrumentation amplifiers play a crucial role in medical devices due to their precision and ability to amplify low-level signals in the presence of noise.

- Electrocardiograms (ECGs): Instrumentation amplifiers are used in ECG machines to amplify the small electrical signals produced by the heart. They provide high common-mode rejection, ensuring that noise from external sources does not affect the signal quality, which is critical for accurate heart function monitoring.

- Electroencephalograms (EEGs): In EEG devices, instrumentation amplifiers capture and amplify the electrical activity of the brain. Their high input impedance prevents loading of the electrodes, allowing for precise measurement of brain waves while minimizing interference from muscle activity or other electrical noise.

- Patient Monitoring Systems: These systems utilize instrumentation amplifiers to monitor various physiological signals, such as blood pressure and temperature. The amplifiers ensure that even the faintest signals are detected and accurately represented in the system, allowing for real-time monitoring and timely medical intervention.

- Medical Imaging Devices: Instrumentation amplifiers are integral to imaging technologies such as MRI and ultrasound. They enhance the quality of the signals coming from the sensors, improving image resolution and diagnostic accuracy, which is essential for effective medical assessments.

- Biomedical Sensors: Many biomedical sensors, such as those used for glucose monitoring, rely on instrumentation amplifiers for signal conditioning. These amplifiers enhance the sensor output, making it suitable for further processing and analysis, thus ensuring reliable measurements critical for patient health management.

What Are the Industrial Applications of Instrumentation Amplifiers?

Instrumentation amplifiers are widely used in various industrial applications due to their high precision and ability to amplify low-level signals in the presence of noise.

- Medical Devices: Instrumentation amplifiers are crucial in medical equipment such as ECG and EEG machines, where they amplify the small bioelectric signals generated by the body. Their high common-mode rejection ratio (CMRR) allows for accurate readings even in noisy environments, ensuring patient safety and reliable diagnostics.

- Industrial Process Control: In manufacturing and automation, instrumentation amplifiers help in monitoring and controlling parameters like temperature, pressure, and pH levels. They convert sensor outputs, which are often weak signals, into stronger, more manageable levels for further processing by control systems.

- Data Acquisition Systems: These amplifiers are essential in data acquisition systems that collect and process signals from various sensors. By providing high accuracy and low noise characteristics, they enable the effective digitization of analog signals, ensuring that the data reflects true system behavior for analysis and decision-making.

- Load Cells and Strain Gauges: Instrumentation amplifiers improve the performance of load cells and strain gauges used for measuring force or weight. They enhance the sensitivity of these devices, allowing for precise measurements even under varying load conditions, which is vital in quality control and structural monitoring.

- Telecommunications: In telecom applications, instrumentation amplifiers are used to boost weak signals for transmission over long distances. Their ability to filter out noise while amplifying the desired signals is crucial for maintaining signal integrity and clarity in communication systems.

How Do You Choose the Best Instrumentation Amplifier for Your Project?

Choosing the best instrumentation amplifier for your project involves considering several key factors that impact performance and suitability.

- Gain Precision: The gain setting of an instrumentation amplifier is crucial for accurately amplifying small differential signals. Look for amplifiers that offer a wide range of gain settings with minimal error to ensure high fidelity in signal processing.

- Input Impedance: High input impedance is essential to prevent loading effects on the signal source. A good instrumentation amplifier should have an input impedance in the megaohm range, which allows it to capture weak signals without affecting the signal integrity.

- Common-Mode Rejection Ratio (CMRR): CMRR indicates how well the amplifier can reject common-mode signals, such as noise or interference present on both input lines. A high CMRR is vital for applications in noisy environments, ensuring that the desired differential signal is accurately amplified.

- Power Supply Requirements: Consider the power supply requirements of the instrumentation amplifier, including voltage levels and current consumption. Some applications may require low-power devices suitable for battery operation, while others may need amplifiers that can operate at higher voltages for more robust performance.

- Temperature Range: The operational temperature range of the instrumentation amplifier can affect its performance in various environments. Ensure that the selected amplifier can function reliably within the temperature range expected for your application to avoid drift or failure.

- Noise Performance: The noise characteristics of the amplifier can significantly influence the overall system performance. Look for instrumentation amplifiers with low noise figures and a specified noise density to minimize unwanted signal interference.

- Package Type: The physical package of the instrumentation amplifier affects its integration into your project. Choose a package type that fits your layout requirements, considering factors such as size, heat dissipation, and mounting options.

- Cost and Availability: Finally, the cost and availability of the instrumentation amplifier should be taken into account. Balancing performance with budget constraints is essential, so assess multiple suppliers and options to find the best fit for your project’s financial considerations.

What Specifications Should You Consider Based on Your Needs?

When selecting the best instrumentation amplifier for your needs, consider the following specifications:

- Gain Range: The gain range specifies how much the amplifier can increase the input signal. A wider gain range allows for flexibility in various applications, making it suitable for measuring small signals in noisy environments.

- Input Impedance: High input impedance is crucial for instrumentation amplifiers as it prevents loading effects on the sensors being measured. This characteristic ensures that the amplifier does not significantly alter the circuit it is measuring, leading to more accurate readings.

- Common-Mode Rejection Ratio (CMRR): CMRR indicates the amplifier’s ability to reject common-mode signals, such as noise that appears on both input lines. A higher CMRR is essential for applications in noisy environments or when measuring differential signals to ensure that only the desired signal is amplified.

- Bandwidth: The bandwidth of an instrumentation amplifier defines the frequency range over which it can accurately amplify signals. Choosing an amplifier with an appropriate bandwidth is vital to ensure that the amplifier can handle the frequencies present in your specific application without distortion.

- Power Supply Requirements: The power supply voltage and current specifications are important for ensuring compatibility with your existing system. Some amplifiers may require dual supply voltages, while others can operate on a single supply, affecting overall circuit design and complexity.

- Noise Performance: The noise performance of an instrumentation amplifier is crucial, especially in precision applications. Lower noise levels contribute to better signal integrity and ensure that the amplified signal is as close to the original as possible.

- Temperature Range: The operating temperature range of the amplifier is important for applications in environments with varying temperatures. Ensuring that the amplifier can function reliably within the expected temperature range can prevent performance issues over time.

- Package Type: The physical package of the instrumentation amplifier can influence the ease of integration into your project. Different package types may offer various advantages in terms of size, thermal performance, and mounting options.